While everyone is still drunk from eggnog and gingerbread house, I am back in the office to resume what I left behind from last week! My short "Happy Holidays" with my Mum in Washington D.C was lovely. We don't really celebrate Christmas so there wasn't any decoration at home but Mum got so many invitation for Christmas party. We went to about 6 parties and it was so exhausting yet fun, the presents part that is!

So here I am recapping from last week, the activities before everyone vanished into their winter holiday.

Many sales man samples and proto samples came in from our factories in China. A lot of the samples turned out promising as one would always expect. But there were a few that didn't come up as nice especially in the knits category. I'm guessing due to the high volume of sampling for Spring 2013 and Fall 2013 during towards the holidays, workers at the factories had to rush out the samples and put aside the inspection part. Being a production management student at F.I.T, I was able to do my own inspection before passing the samples over to our client.

inspection

inspection

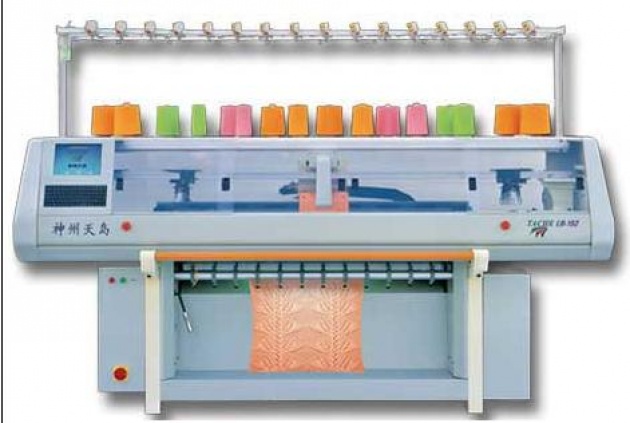

There were defects in terms of measurement and design. In woven garment, as you might know, when in sampling process, a faulty garment can be reproduce again by using any available fabric to achieve desirable specification. But in knitted garment, it has to be knitted again using a computer operated knitting machine to make the garment. The process is much more complicated and takes more time especially for texturally complexed knitted garments.

The machine operator has to revise the client's design and put in back into the machine. Examples of the areas that need to be fix are the length of the sleeves, the height of the neck, or even the curve of the waist area. However, if the selected yarn that client wanted ran out, we would be in trouble! Because then client has to order more yarn for the factory to use in sampling. When that happens, the delivery date would be delay further.

When you bought a sweater at a sample sale and then at home you check on the brand's website to compare the actual retail price and look, you realized that the design is not the same as how it looked on the website. That's because the garment you bought is the defected sample garment, not the finalized version.

This is what a knitting machinery in a factory looks like

What I'm really saying is, garment inspection is crucial in the process of product development. Every little detail in a garment is very important, but it's up to the client whether it's good enough or not for them to proceed to full apparel production. In short, nothing is perfect. But we must strive for perfection as much as we can!

[ L to R: Peter Pilotto SS13 | Alexander Wang SS13 | Paco Rabane SS13 ]

[ L to R: Helen Rodel SS13 | Alexander McQueen | Jean Paul Gaultier Spring 13 ]

For those who are still "out of the office" I wish you Happy Holidays and Happy New Year! See you in 2013!