My "How To" series, I will try to make some tutorials about some projects we made on our Engineering subjects and somethings I do online. I will try to make this tutorial as simple and as basic as possible while tackling some basic information and process on building or using a tool.

I am not an expert so these guides may not be the best and are based on what I learned, how I experienced building it or how I do things. I am open for correction for I am also willing to learn from everyone, thank you. Enjoy.

On this episode, I will teach you how to build a simple power supply capable of converting the power from your house's power outlet into a output that won't harm you devices. Power supply like this, as defined by most of our professors, is an electronic device capable of converting an AC input into a DC output although there are more types of power supply available we will only focus on AC-to-DC converter. Modern devices required a constant DC supply to work properly without interruptions, one good example of this is our modern computers which hold important information from time to time that if supplied constantly prevents corruption of our precious data.

The concept of AC power is important in building a power supply because it is the power used in most of our houses. As we know, supply of power are generated from power plants then distributed commercially by electricity providers. Here in Philippines, Meralco is the number one electricity provider.

Let us first build our power supply then I will explain what's happening inside the circuit of our project.

Materials and Tools:

1. Power Cord

2. Switch

3. Fuse and Fuse Holder (0.75 to 1 Ampere)

4. Transformer (220 or 110 V input depending in your household's supply with an output voltage above your target supply output, for this project we will need 9 to 12 V output since our target is 5 V, this will be explained later.)

5. Atleast 4 pcs of diode (1N4001)

6. Capacitors (atleast 1 pc of 1000uF and 1 pc of 100uF both should have volt rating the same or above our target output)

7. Resistors (atleast 2 pcs of 1k ohms)

8. LED (Light Emitting Diode) / indicator

9. Voltage Regulator (7805) and heat sink

10. banana jack/alligator clip/female usb as output

11. PCB (Printed Circuit Board)

12. Ferric Chloride

13. Soldering Iron

14. Solder (lead)

15. Wires

16. Non-metal container big enough to contain your pcb but not so big to avoid wasting your ferric chloride

17. Marker

18. Cotton and Acetone

19. cutter or small saw

20. Drill

21. Sand Paper 1000cc

22. Desoldering Pump (optional)

23. Wire Stripper (optional)

Procedure:

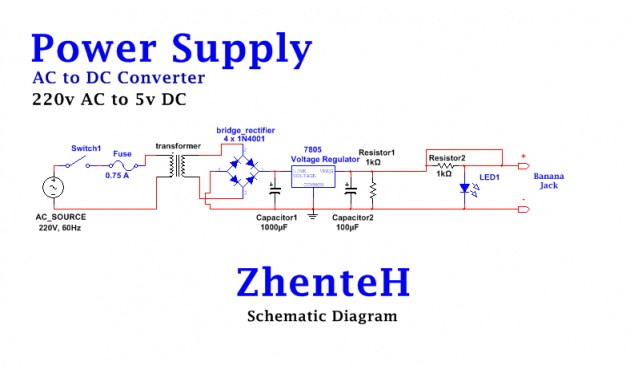

We will be using this schematic diagram for our power supply project. I created this circuit using the software NI Multisim.

Screen Capture of schematic diagram for 5V power supply by ZhenteH

1. Design a circuit based on our schematic diagram using any software like multisim/ultisim, eagle, PCB wizard or any other software that you know. Alternatively you can manually create your own on a piece of paper since we will not use a special treatment for our circuit. You may also use our PCB design if like.

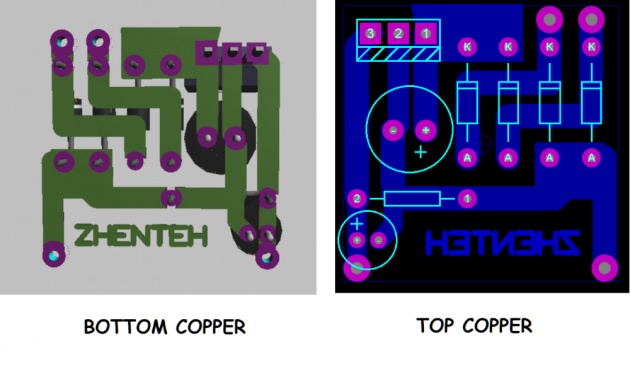

PCB design using Proteus by ZhenteH

2. Cut your PCB to the desired area. If you are going to use a cutter, do not use it's blade because it will damage the blade of your cutter instead use the back blade then draw a line at the back of your PCB. A size of 2.5 x 2.5 inches of PCB can be used.

3. Clean your PCB and smoothen it using a 1000cc sand paper while avoiding to touch the copper part then if you are going to rest or won't continue for now cover your PCB with paper or anything alike so that the copper part is protected from dust and oil.

4. As I said we will not do special treatment since we are only using a cheap PCB but instead we will just copy our created PCB design to our PCB using our marker, make sure to make it as clearly as possible to avoid a spots when its done.

5. After you transfer the design, place the PCB on a small non-metal container and pour a good amount of ferric chloride. Shake it carefully.

Please be advised that ferric chloride is dangerous to your skin and may cause irritation since ferric dissolves metal and our skin has iron and other metal-like element and this is also the reason why we should not use a non-metal container.

6. Wait until the copper of the non-marked part are dissolved.

7. Prepare another container and pour some water then transfer your PCB using a non metal holder and rinse your PCB.

8. Pour some acetone on a piece of cotton, wipe out the marked lines until you can see your design. On this part you can see your design in copper just like those circuit in your electronics devices.

for a sample PCB making using a marker and dissolving a copper you may watch this.

How to make PCB using MARKER PEN (Printed Circuit Board) by DIY Project via youtube

9. Drill the hole on the designated part of your design. Make sure that these holes is just enough to hold your components.

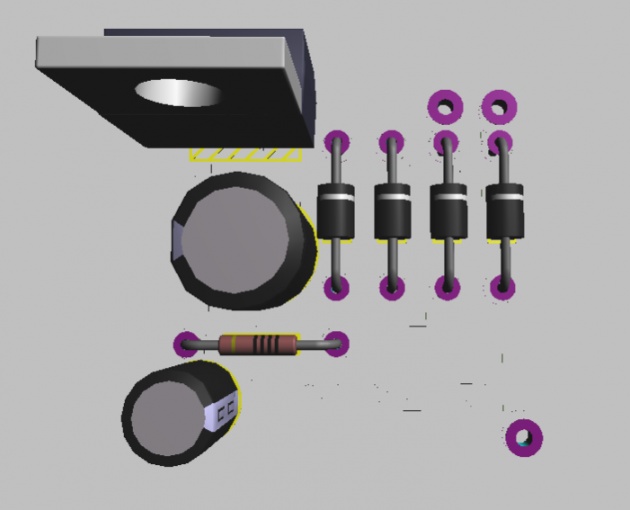

10. Place each component in their corresponding places, be sure to check the polarity of your components. Connect a heat sink on your voltage regulator to reduce the heat it will produce that may damage your circuit.

11. Solder each of your component properly using your soldering iron and soldering lead, then cut the excess part of your soldered components. Make sure the jumper wires are also soldered. If you think you have to undo the solder, use a desoldering pump after heating the lead.

for proper guide on how to solder

Soldering: The Dos and Don’ts by jcbtools.com

12. Set aside your circuit in clean and dry place. You can now work on the design of your casis considering the holes for power cord, fuse holder, switch, LED (indicator), screws that will holds your things and your output which can either be a alligator clip or babana jack.

13. Place your circuit board and transformer on your casis. Connect the output part of your transformer to the input part of your circuit considering their polarity.

14. At one side of your casis, place the switch, the power cord and the fuse holder then using your wires connect them according to our schematic diagram and lastly connect their output on the input of your transformer.

15. At the other side, place your LED and output on their respective places. Before connecting the LED to your circuit, be sure to have a limiting resistor (1k ohms) so your indicator will not be damaged instantly.

16. Build, complete and enclose your power supply. You can now test it and congratulate yourself for creating your very own simple 5V AC-to-DC inverter.

5 V AC-to-DC power supply circuit broad in 3D simulation by ZhenteH via Proteus

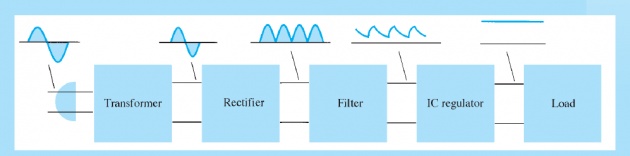

After building our circuit, let me explain a few things about the inside of a power supply. As I learned from my past electronics subjects, Power Supply is basically consisting of few stages: AC supply, transformer, rectifier, filter and regulator circuits.

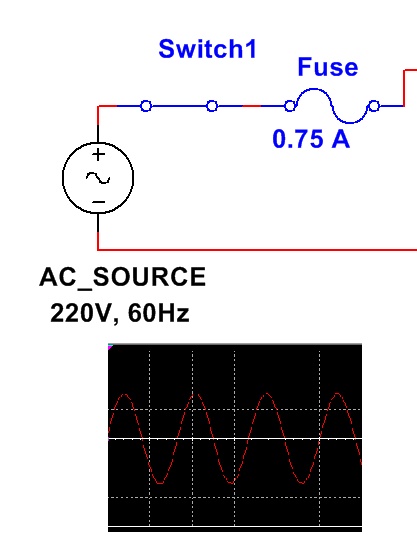

AC supply, this is the first stage of our project. This stage starts from the AC source of your house's outlet which normally supplies 110V in some countries or 220V in other countries like here in Philippines and has a cycle of 50-60 Hz. We can consider the switch and fuse to still be included in this stage since the voltage, current or frequency from the supply upto them is still the same.

The fuse is an important part of our circuit that protects the circuit from sudden power spikes from your house's socket. It is designed to melt or cut its connnection if there's a sudden over flow of current which disconnect the rest of your circuit and prevents damaging the rest of your component. Fuse can also be found on your home's fuse box which has the same purpose of protecting your appliances and the rest of your house.

the switch connects the ac input to the other side of your circuit. When you turn it on the switch closes the gap between the left and the right side of your design which means a supply passes through and when you turn it off it opens the gap which prevents the supply to pass through. We can simplify it as when it is on the circuit is connected and when it is off the circuit is disconnected.

AC waveform (200 volts/division) by ZhenteH via NI Multism

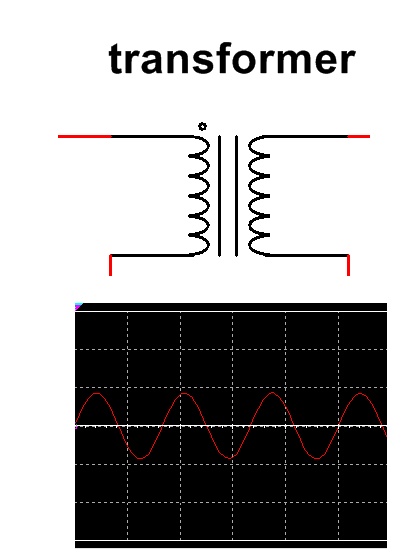

We can divide the types of transformers as step-up and step-down transformers. Step-up transformeras the name indicates transforms a supply to a higher output, this is often seen on power plants that supply electricity to up its power while transfering the electricity so power loss is covered while step-down transformer transforms a supply to a lower output just like the transformers you seen on electric poles and what we are using in this project.

A transformer has primary winding and secondary winding that are physically not connected to each other but due to electromagnetic induction which follows faraday's law they are able to transfer energy from the primary to the secondary winding.

AC waveform after it passes through the transformer by ZhenteH via NI Multisim

In this project, the 220V voltage supply is transformed to a much lower output which is 9 to 12 volts.

Rectifier is used to change the AC power into pulsating DC. There 2 types of rectifiers:

1. the half-wave rectifier that uses a diode which removes half of the input signal to establish a DC level output. During the positive half cycle, the diode is foward biased and lets the current to pass through while on negative half cycle, the diode is reverse biased and acts as a open switch that prevents current from entering. These biasing prevents the negative half of the wave and leaves only the positive half on the output.

2. The full-wave rectifier which is composed of two different approach:

A. Center-tapped uses a transformer that has a tapped in the middle and 2 diodes, this kind of rectifier, unlike the half-wave rectifier, uses both the positive and negative half cycle of the input wave to establish a DC output. Since both cycle is used, there is a continuous pulsating DC output unlike the Half-wave that has a positive and 0 half cycle. This kind of rectifier significantly reduces the output voltage which means you will need to have a higher input voltage to produce a good amount of output.

3. The bridge type rectifier is the most popular configuration for performing a full-wave rectification. It covers both the disadvantages of the two previous configuration. It supplies a continuous pulsating DC output and has less voltage loss unlike the center-tapped. This type uses 4 diodes that forms a bridge connection, during the positive half cycle 2 diodes let the positive charge to pass while 2 diodes prevents the negative charge and these pairs interchange during the negative half cycle which produces a better full-wave pulsating DC output.

Bridge Rectifier by LearnEngg .com via youtube

The diodes used in these configuration usually has a loss of 0.7 V, this is the reason why we need a higher output from our transformer and that is to have enough supply after each stage. Since diode requires 0.7 V it will not turn on until it is given a voltage higher than 0.7 V.

Although an output of a rectifier is DC, it still has ripple that can still damage your load. This is the main reason why filters are installed on most of the power supply - to prevent ripple components from appearing on the output. Filters are designed to convert the pulsating DC from rectifier circuit into a suitably smooth DC level, it also smoothen the signal and minimize the AC components. The ripple factor determines the effectiveness of the filter used in your circuit, the lesser the ripple the more effective the filter.

Filters can be a capacitor which is the most economical and simplest filter. RC-filters or the combination of resistor and capacitor is also used to reduce the ripple voltage across the capacitor.

But how does filter works? Capacitor is like a battery that stores energy then discharge it when it is full. This charging and discharging covers the time that the voltage level is supposed to down which results in less ripple and smooth DC output. The resistor acts as a limiting resistor that prevents excess current from entering, this filter supplies only the correct amount of current to the output which gives a better result and smoother output.

Ripple Voltage after it passes through the filters by web.sonoma.edu

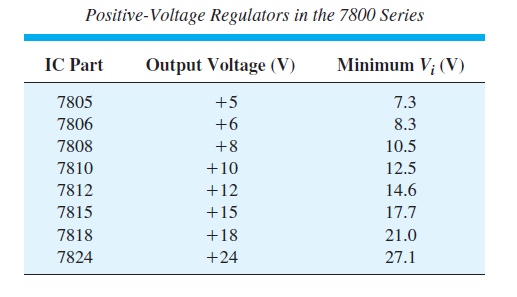

We can further smoothen the output voltage of our power supply by using a voltage regulator. In this project we used an IC voltage regulator that belongs to the 78xx series. 78xx series gives a fixed positive output voltage even if the input supply changes. The xx digit of the 78xx implies the out voltage of your voltage regulator for example 7812 has positive 12 volts output, while 7809 has positive 9 volts and the one that we are going to use, 7805, gives a fixed positive 5 volts output. Although these regulators have a fixed output they need a minimum input voltage to properly produce their designated output.

list of 78xx series voltage regulator, their minimum voltages required and their output voltages

From Electronic Devices and Circuit Theory by Robert L. Boylestad and Louis Nashelsky

These list are the minimum but it is always advice to stick as close to the minimum as possible because the excess energy that the regulator receive will be desipated as heat. If you have too much heat that your device can not tolerate it will damage the circuit. This excess heat can be minimized by using a heat sink that will absorb the excess heat and destribute it properly and lessen the danger in your power supply.

The load

A simple 5 volts power supply, 5 volts power supply can power a lot of electronics devices this includes your cell phone. Yes, this means you can use this as a charger for your phone although it is a lot cheaper if you buy and actual charger.

Block Diagram of a Power Supply From Electronic Devices and Circuit Theory by Robert L. Boylestad and Louis Nashelsky

So thats it, congratulations you have completed your power supply.

If you want to change the output voltage that your power supply will give, you just have to change the transformer's output, the capacitor with the same or higher voltage rating as your desired output and the regulator 78xx.

That will be all for now. If you think I have done or stated something wrong please don't be shy to mention it, I am willing to learn from everyone.

I hope you enjoy this tutorial and you get something useful.

Buzzed up and comment.

Share on social media (facebook, twitter and google+).

----------------------------------------------

Do you want to earn while doing something you do on facebook or twitter or instagram?

Do microblog, upload your photos and videos and post big time blogs!!

Interact with other members and earn.

Come on join us @Bitlanders