In part 1 I told you about its definition, formal parts names….so, in this blog I will tell you about its functionality working …proper maintenance and all stuff about this important machine in any industry….

We can do maximum operations ever on this machine that’s why this machine is basically very important….now we are starting with remaining parts name…

Chuck:

we can locate our job in chuck which has different sizes and patterns. Formally 3 jaws chuck using in industries because of his universal functions but on the other hand 4 jaws chuck also uses for different operations on their needy basis..

In 3 jaws chuck we can locate or hold cylindrical or round job/work piece. These 3 jaws move up and down with chuck key s for holding work piece. Where’s 4 four jaws chuck uses for rectangular or irregular shapes work piece.

The only difference between in these two chucks is that, in 3 jaws chuck we can locate or dislocate our work piece without moving ever jaws slot. We can put chuck key in any jaws slot and we can easily hold/un hold our work piece… where in 4 jaws chuck we put keys in every jaw and tight or lose the job.

If any jaw of 3 jaws chuck is destroys we should replace whole chuck instead of one jaw where’s ion 4 jaws chuck we do change only destroyed jaw.

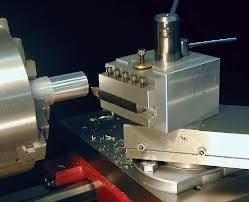

Tool Post:

For the rest of tools there is a special kind of tool post is mounted. We locate our specific tools in this tool post and done we required operations. Too post is located on top of sliding carriage or rest of compound slide.

Bed ways:

more importantly is that special type of bed ways with great accuracy is located below the carriage which are well finished and had material. Carriage and tail stock slides on this bed ways.

Writer: Waleed Altaf