The spinning of synthetic man-made fiber is of three types.The first type is melt spinning.The second type is wet spinning and the third type is dry spinning.Now here we are going to understand the melt spinning process process.Naturally the polymers which make synthetic man-made fiber are always exist in liquid state .The polymers are entered in the appratus which is called as spinning plates or spinning jeks having small pours in their bottom surface.These jeks or plates are may be in circular triangular or rectangularshape.These are same as washing shawers.

The polymers are entered in the selected plate and will be collect in a collector when the polymers are come out from the spinning jek,then cooled air passed out from the polymers due to which shape will permanent.Only those polymers are passed out from the melt spinning which are not decomposes.In melt spinning process,thee pressur will be applied through a pressure pump by which a continuous and yarn like thing will be obtained.

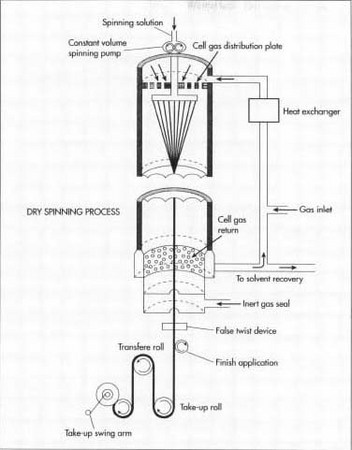

Dry spinning is a type of spinning of man-made synthetic fiber.In this process we take a solution having very low boiling point and mixed or blind the polymers with the dry spinning. Then we put this mixture in the spinning jek same as in the spinning jek in melt spinning.Also dry spinning jek plays a role just like the washing shawer.We put the combination of solution and polymers in the spinning jek which with help of a pressure pump is sprayed out from the soinning jek and collected on a collector after the spray.And then hot air is passed out from the sprayed mixture due to which the solution is evapourated because the solution has very low boiling point and we collect only the polymers on the collector.dry spinning can be done only if polymers decomposes.The shape of the spinning jek in dry spinning is may be circular,rectangular or triangular etc.In dry spinning the solvent will evapourate and only the polymers left behind.