UberBlox is proof, if proof were needed, that the tech world is increasingly modular in its thinking. Want to this, that or the other on your phone? There’s a grab-bag of apps for that. Need to build an app? There are code libraries and APIs to plug into. Building some hardware? Additive printing can extrude the pieces for you to put together. Slot in a Raspberry Pi and your gizmo gets a brain. Bish, bash, bosh!

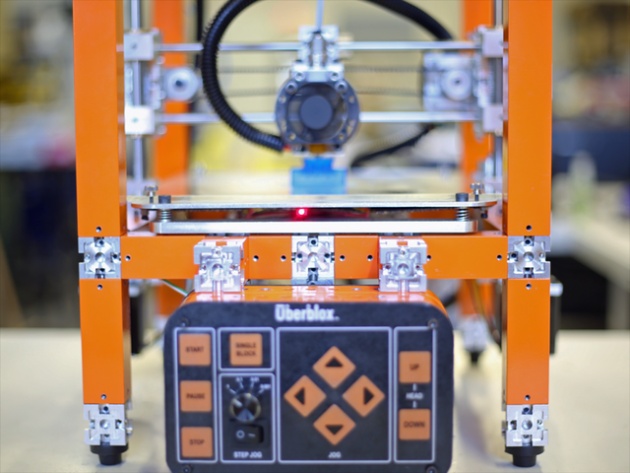

Picking up this modular baton and running with it is UberBlox: a modular construction system consisting of discrete, standardized parts for making reusable metal skeletons to house your hardware project. Think of it as akin to Lego but more durable, given these blocks are precision manufactured metal bars with metal connectors called nodes that allow the pieces to be screwed together.

Dynamic modules are also included in the kit, so your metal constructions can include moving parts and components. There are also some modules with full functions, such as a laser module capable of engraving and cutting. And a sub-system for integrating electromechanical components, such as motors and actuators, into builds. Microprocessor components can also be integrated via a dedicated “Brain-Box” component — that contains either an Arduino or a Raspberry Pi.

Founder Alex Pirseyedi, who has a background in mechanical and software engineering, says UberBlox aims to slot in the gap between cheap plastic building blocks and more skilled building processes for fabrication that are used to create more rigid and elaborate structures.

“As great as building blocks are, they don’t address the need to build more robust structures. Anyone interested in making things like machines that actually do things, accurately, is generally stuck with either having someone else build it for them, or take the years to develop skills needed to get good at design and fabrication, then spend long hours on building their designs,” he tells TechCrunch.

Pirseyedi says the most similar traditional metal building systems to UberBlox are products like T-slot aluminum extrusions. But the difference with UberBlox is the pieces are designed to be used without needing to modify them by drilling or cutting and so on, so they can be reused again and again.

He also argues that taking a more modular approach to construction can make it easier to design whatever it is you’re trying to make in the first place — because the standardized pieces can help suggest the structure.

“Having used systems such as T-slot extrusions for years for designing machines, I often had to deal with a great deal of design choices. That may sound like a good thing at first glance. But it could also introduce ‘analysis-paralysis’,” he says.

“The fact that you are not forced into using simple discrete parts that are given to you as exact individual tools you get used to use over and over again, makes you have to think and over-think your design, or even wonder where to begin. I also found that the large number of connection options of these other systems cause you to have to make slow design decisions and sometimes be stuck with settling on certain design details.”

Who is UberBlox for? The maker community is a clear target but Pirseyedi also sees potential in various other areas such as light manufacturing, architectural and structural design.

Another focus is education. “STEM and edTech are a great focus for us. Several university engineering departments have already shown interest in working with us to bring this system into their offering as a powerful tool to teach engineering skills, in mechanical and structural design as well as programming of automated machines,” he adds. “We believe strongly in this system can help people who are trying to learn and/or improve their machine building and programming skills.”

At this point UberBlox remains an aspiration. Pirseyedi is currently raising funds onKickstarter to get his metal kits to market later this year. He’s after $100,000 to do that and is only around a third of the way there with just over 20 days left of his campaign to run so a successful crowdfunding is still some way off.

The cost of the construction kits might give some makers pause. A ‘pick your own selection of parts’ kit option requires a $399 Kickstarter pledge, although less fulsome kits cost less. Pirseyedi says UberBlox are priced competitively with T-slot systems but again emphasizes the re-use point as an advantage over those alternatives.

“You are getting an intricate high quality metal part that you can keep re-using for decades as part of a modular system that gives you efficiency, flexibility, re-usability, and ease of use,” he says. “The point is, you spend less in the long run both in tangible dollars and in the time it takes to put something together. That’s the value this system brings to you.”